our services

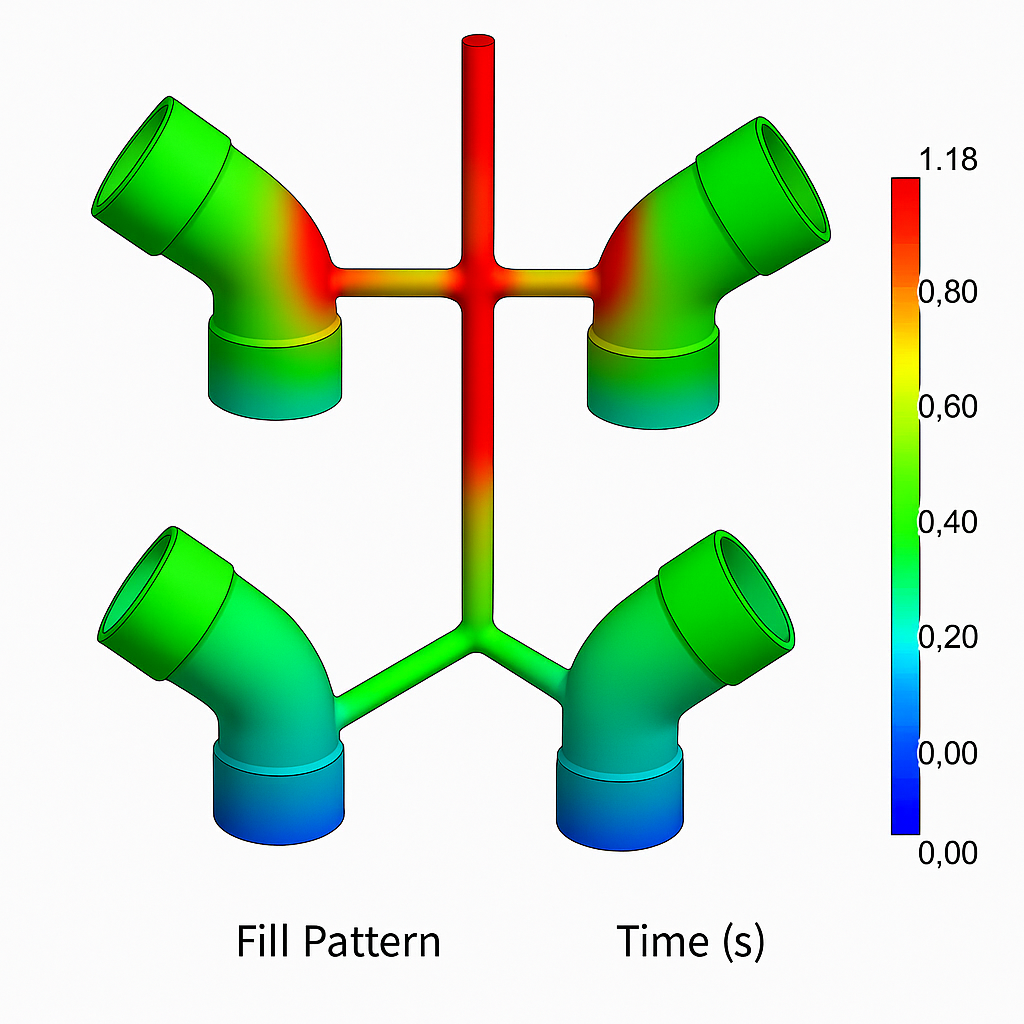

Plastic Injection Simulation

KAZILEO has over 20 years of experience in the plastics processing industry — including mold design, tooling engineering, and injection process setup.

This combination of design expertise and production know-how allows us to provide not only design services but also complete process optimization and production startup consulting.

- 20+ years of experience in mold design and polymer processing technology.

- Advanced CAD/CAE tools for accurate flow, cooling, and deformation analysis.

- Expertise in glass-fiber reinforced polymers (PA6, PA66 GF) — fiber orientation and warpage prediction.

- Pre-production optimization – reducing tool rework and validation time.

- Comprehensive technical reporting – detailed process data and design recommendations.

For more than 10 years, we have worked with injection molding simulation software to analyze flow behavior, cooling efficiency, shrinkage, and warpage.

We also specialize in simulations of fiber-reinforced materials, such as glass-filled polyamides (PA6, PA66 GF) — evaluating fiber orientation, warpage prediction, and dimensional stability of molded components.

These simulations predict material behavior within the mold, identify potential design or process issues, and help optimize both part geometry and mold performance before production begins.

The results help reduce testing time, eliminate tooling corrections, and improve part quality, ensuring stable, repeatable, and cost-effective manufacturing.

All analyses are performed using professional CAD/CAE tools, and reports include detailed data on pressure distribution, temperature gradients, cooling times, fiber orientation, and deformation mapping.

KAZILEO – engineering precision through simulation, prediction, and process optimization.

OUR SERVICE BENEFITS

Experience Innovation

the Professional Way

At Kazileo, every simulation project combines engineering precision with advanced polymer flow analysis to deliver results that directly support production efficiency.

We transform digital data into actionable insights — identifying critical zones, optimizing cooling circuits, and defining stable process windows before the first trial shot.

Our experience in both virtual analysis and real injection molding processes ensures that every recommendation is practical, implementable, and production-proven.

- Data-Driven Process Optimization – we base design and process decisions on simulation data, not assumptions.

- Reduced Time-to-Production – fewer mold corrections, faster tool approval, and shorter validation cycles.

- Improved Product Quality – optimized flow and cooling balance minimize warpage and internal stresses.

- Material-Specific Expertise – deep understanding of glass-filled polyamides and technical polymers.

- Full Engineering Support – from simulation to process validation and production launch.

Kazileo – turning simulation results into real production performance.

Testimonials

What our

clients say

Real cost savings and better process control

“The simulations performed by the Kazileo team allowed us to identify flow and cooling issues before the mold was even built.

Their analysis helped us reduce testing time by over 30% and completely avoid costly tool corrections.

The technical report was exceptionally detailed and perfectly clear for our process engineering team.”

— Technical Manager, Automotive Components Manufacturer

Accurate warpage prediction for glass fiber–reinforced parts

“Kazileo carried out a series of injection simulations for parts made of glass-filled polyamide.

The results on fiber orientation and warpage matched our real production tests with impressive accuracy.

It was the first time we received such reliable data at the design stage.”

— Senior Process Engineer, Technical Plastics Supplier

Professionalism and deep process understanding

“The Kazileo engineers not only provided simulation results but also thoroughly explained them and recommended precise improvements for both tool design and process parameters.

Thanks to their input, we eliminated sink marks and achieved uniform filling in all mold cavities.

Their engineering mindset and real-world molding experience make them a highly reliable partner.”

— Product Development Manager, Industrial Equipment Manufacturer

OUR SERVICE BENEFITS

Experience Innovation

the Professional Way

Our research phase is very important. We do our best to plan every possible outcome, which would affect the budget and time of finishing the project:

- Based on your project, get only what's needed

- Cost effective, to secure construction process

- Premium quality. We always get the best people

Through this experience Warmhouse has acquired a high level of expertise in the design and realisation of high-profile and luxury schemes.

Testimonials

What our

clients say

Let’s Get in Touch

Contact details

Phone: +48 793 155 050

E-mail: info@kazileo.pl

Address: 27 Grudnia 3, 61-737 Poznań, Poland

Opening hours:

Monday — Friday 08:00 – 16:00