our services

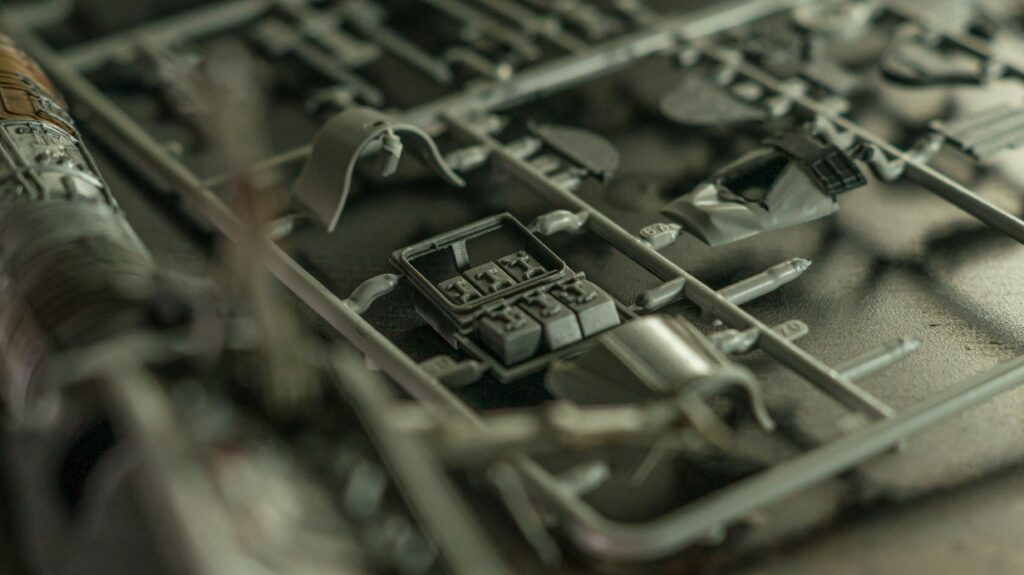

Injection mold design

At Kazileo, every mold begins as a precise engineering concept — not just a 3D model.

Our design philosophy integrates mechanical accuracy, polymer science, and production data to create injection molds that deliver consistent, repeatable performance. Each design process is guided by detailed manufacturability studies, mold flow simulations, and dimensional stability analysis to ensure the final tool meets the highest technical and production standards.

We specialize in customized mold solutions for complex plastic parts, where precision, cooling efficiency, and tool longevity are crucial. By combining advanced CAD systems with data-driven simulations, we identify potential challenges early — reducing development time, minimizing rework, and improving overall productivity.

Why Choose Kazileo:

- Simulation-Driven Design – Every project is validated through flow, cooling, and warpage analysis before manufacturing begins.

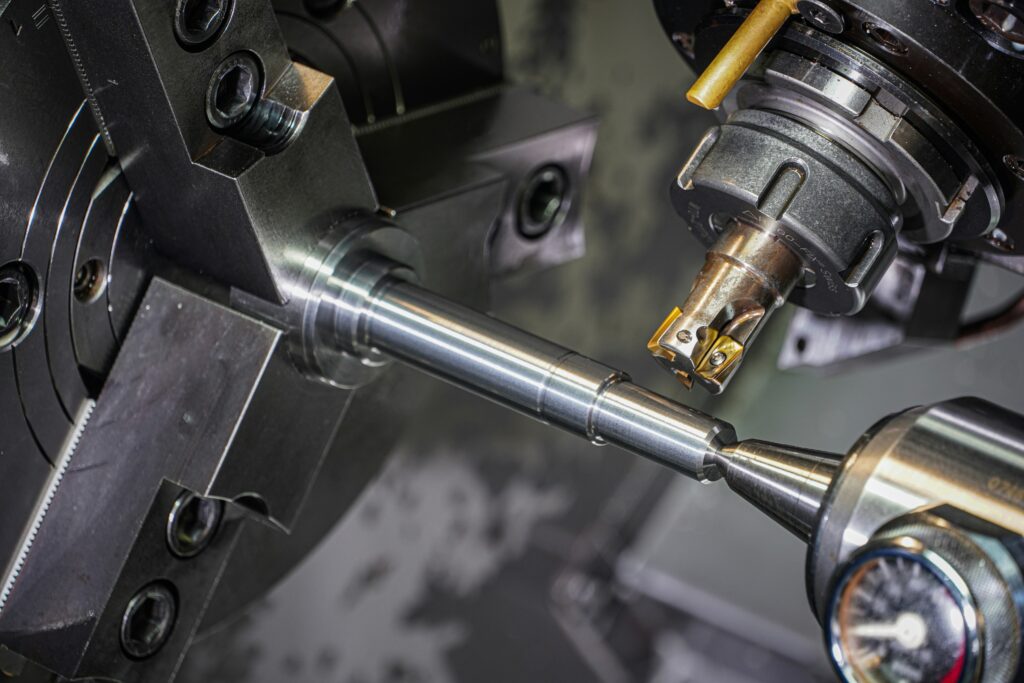

- Engineering Precision – Our molds are designed with micron-level accuracy using advanced CAD and CAM systems.

- Certified Production Expertise – Full compliance with international quality standards: IATF 16949, ISO 13485, and FDA guidelines.

- Optimized Tool Longevity – We focus on durability and serviceability, reducing downtime and maintenance costs.

- Integrated Development Process – Seamless collaboration between design, machining, and validation — ensuring faster, more reliable results.

Our experience spans multiple industries, including automotive, medical, and industrial components, where quality and compliance with standards such as IATF 16949, ISO 13485, and FDA are non-negotiable.

Every Kazileo mold is engineered to balance durability, cost-effectiveness, and ease of maintenance, ensuring a stable production process over thousands of cycles.

OUR SERVICE BENEFITS

Experience Innovation

the Professional Way

At Kazileo, every project is driven by precision, data, and engineering integrity.

Our approach combines advanced design tools, simulation technology, and production experience to ensure measurable performance, reliability, and long-term value.

From concept to qualified production, we deliver solutions that minimize risk, optimize cost, and enhance process efficiency.

Key Benefits:

- Process Optimization – Improved cycle times and reduced tooling wear through simulation-driven design.

- Certified Quality – Compliance with IATF 16949, ISO 13485, and FDA standards.

- Reduced Development Time – Integrated CAD, CAM, and CAE workflows accelerate project delivery.

- Cost Efficiency – Smart engineering decisions that balance durability with manufacturability.

- Reverse Engineering Expertise – Precise reconstruction and regeneration of legacy components.

- Reliable Support – Ongoing technical assistance from design to production validation.

Through years of engineering experience, Kazileo has developed advanced expertise in the design, optimization, and qualification of high-precision tooling and plastic injection systems.

Testimonials

What our

clients say

Kazileo delivered a complete mold design that perfectly matched our production requirements.

Their attention to detail and understanding of injection molding processes saved us significant tooling time.

The design was ready for manufacturing without a single revision.”

— Production Manager, Automotive Components Manufacturer

Working with Kazileo was a seamless experience.

Their engineering team supported us from concept through mold validation, combining CAD precision with practical moldflow insights.

The end result — a stable, efficient tool that performs flawlessly in series production.”

— Tooling Engineer, Plastics Processing Plant

Kazileo helped us redesign a complex multi-cavity mold under tight deadlines.

Their ability to optimize cooling and part ejection made a visible difference in cycle time and product consistency.

We highly recommend them for any precision tooling project.”

— Technical Director, Medical Device Supplier

OUR SERVICE BENEFITS

Experience Innovation

the Professional Way

Our research phase is very important. We do our best to plan every possible outcome, which would affect the budget and time of finishing the project:

- Based on your project, get only what's needed

- Cost effective, to secure construction process

- Premium quality. We always get the best people

Through this experience Warmhouse has acquired a high level of expertise in the design and realisation of high-profile and luxury schemes.

Testimonials

What our

clients say

Let’s Get in Touch

Contact details

Phone: +48 793 155 050

E-mail: info@kazileo.pl

Address: 27 Grudnia 3, 61-737 Poznań, Poland

Opening hours:

Monday — Friday 08:00 – 16:00